Series 3D Printed Computer Mount for Garmin and Wahoo produced for Canyon Bicycles

Still not convinced a 3D printed product can be a series manufacturing runaway success? The Forward AM | Canyon Garmin PA11 CF Bicycle Mount is designed and produced with additive manufacturing and sold out in one week, leading to an almost immediate order of the second batch of parts. These bicycle mounts for on-board computers are a perfect storm of optimization from design to material to manufacturing method – letting the product shine through the competition. rpm is proud to have been chosen as the partner of Canyon Bicycles and BASF Forward AM to produce the two initial AM products, the Garmin and Wahoo PA11 CF 3D Printed Computer Mount.

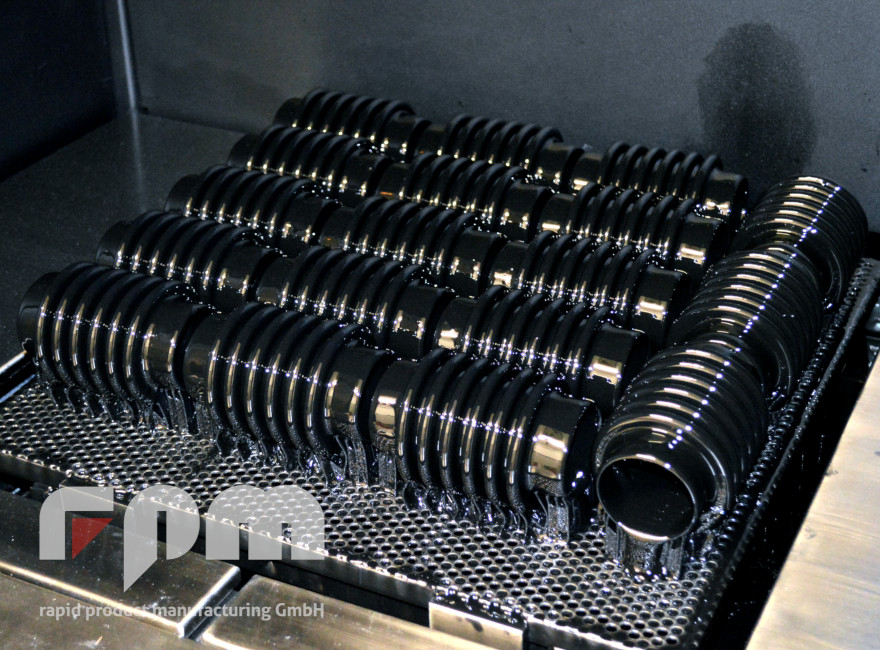

rpm is the production centre for this series additive manufacturing handling all steps from material evaluation to tight machine controls to in-house chemical smoothing and ending with an ISO 9001:2015 quality assurance process. With over 25 years’ experience delivering end-use parts, rpm is also providing full consumer goods to Canyon, packaged with accessories, printed collateral, assembly and packing in a stylish box. With rpm as a partner, Canyon has series quality 3D printing and a full logistics management to deliver consumer parts ready for direct sale.

Design for Additive Manufacturing (Forward AM | Canyon Bicycles)s)

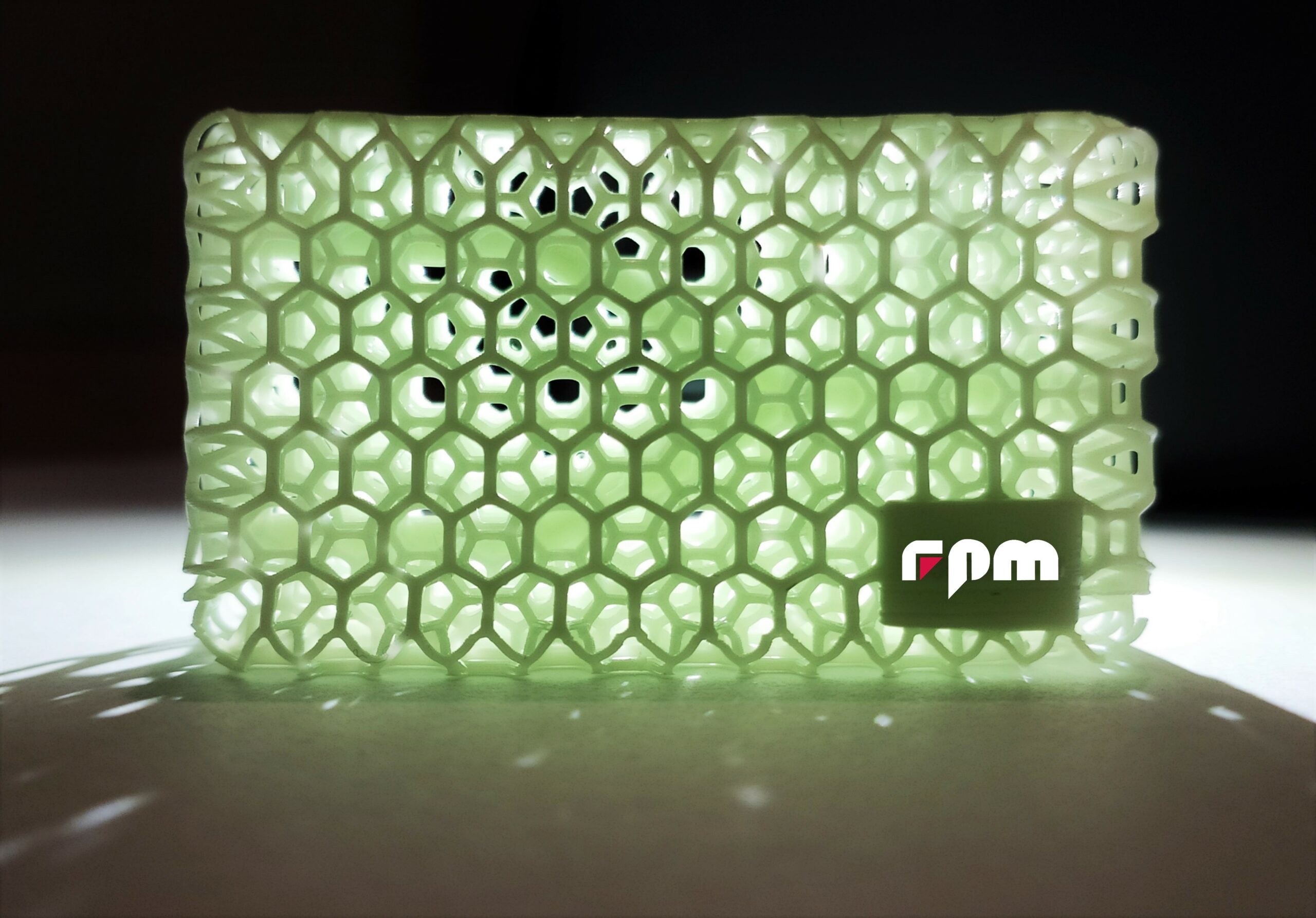

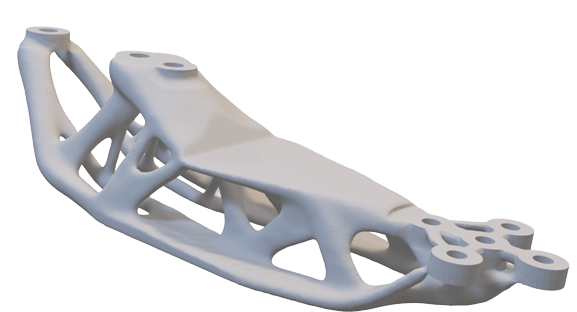

The Forward AM | Canyon PA11 CF 3D printed computer mount is an important lighthouse project for developing series applications for additive manufacturing. The process began with an evaluation of potential parts from the Canyon bicycles which provide the proper mix of business and technical advantages, high value parts that would also benefit from weight saving and high strength/stiffness. The Canyon and Forward AM started PA11 CF (Carbon Fiber reinforced Polyamide 11) as the desired material because of a good processing during production, lightweight characteristics and a high strength to mass ratio for a latticed design.

Foto Source BASF Forward AM : Original Article

The two teams then arrived at a final design by iteratively testing potential parts using the Forward AM simulation tools. This allowed a rapid product development cycle using a digital workflow, tuned specifically to the Forward AM material portfolio. They end design was low weight (17 g) and also provided a long-lifetime and robust shock absorption independent of the terrain where the bicycles were driven.

Foto Source BASF Forward AM : Original Article

Qualified Production for Products from Series Additive Manufacturing

With a business case in hand and an optimized design, the Canyon team was ready to begin testing the parts and looking for a series partner. They turned to rpm rapid product manufacturing GmbH because they were an early adopter of several BASF specialty materials, have over 25 years of experience producing parts with SLS and have an infrastructure for delivering series parts driven for 15 years by their casting and injection moulding business units. While rpm could immediately print prototypes required for product release, the real work began with establishing a series production process to guarantee high quality printed products, ready for direct sale to consumers.

The last stage of Design for Additive Manufacturing (DfAM) also came at this point as rpm adjusted several small features of the approved design to optimize for printing repeatability smoothing and tracking the series production.

Over a couple months rpm worked directly with the Canyon product and Forward AM business teams to validate all the details of production, mechanical performance and packaging to deliver a full-package solution. This includes locking all evaluation parameters for material and processing for production, adding an AMT chemical smoothing system in-house for repeatable local finishing of the parts and managing the production of 2D-printed instruction booklets and external cardboard packaging from local production partners.

This project for series production of 3D printed computer mount is a marker of rpm’s vision for the coming years, to increasingly be a one-stop-shop partner for additive manufacturing products ready for direct sale.