Four Years, Four Machines. Farsoon and rpm add SLS Production Line Automation with Powder Management System (PMS)

On the 19th of February 2020, rpm confirmed the purchase of their first two Farsoon systems, the SS403P and HT403P. Now, four years later, rpm has four systems in total: three CO2-laser systems and one of the first Farsoon Dual Fiber Laser Light (“Flight”) Systems in Europe and brought the Powder Management System (PMS) into operation on the 19th of February 2024. The PMS adds further automation to their additive manufacturing production which is important for cost-competitive production. Equally important, by using machine processing for powder preparation rpm adds process stability for their series products.

Benefits of Machine Powder Processing for SLS Additive Manufacturing

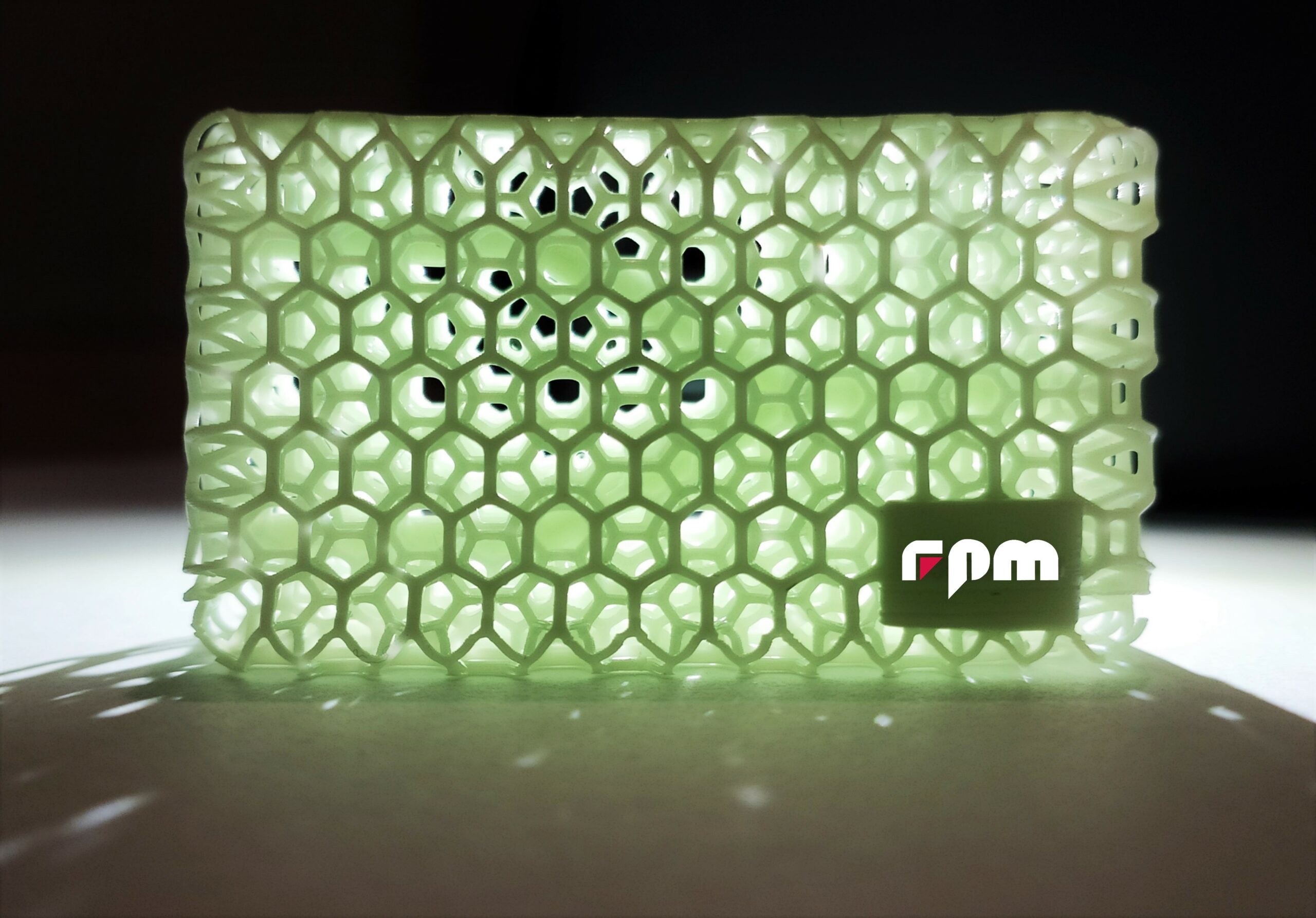

rpm sees several key operational benefits of the Powder Management System. Firstly, the PMS provides a controlled and sealed environment for material handling, minimizing contamination risks and safeguarding material integrity. This feature is particularly critical at rpm as they are known for working with an extensive material palette, as it will ensure consistent quality across various materials. Initially rpm is beginning with their highest usage white material, but the mid-term goal the goal is to extend to additional high-usage materials within our black powders to support the Flight System installed in 2023. This is part of the continuous build-out by rpm of their series additive manufacturing line.

The second primary benefit comes from automating the repetitive task of powder preparation to optimize workforce utilization. As rpm operates in the European market where labour is an expensive cost factor, the Powder Management System and other automation tools are critical to staying cost competitive. This allows our skilled operators to focus on the key aspects production management, to improve efficiency and reduce operational errors. The fast-mixing system also means that there is minimal down-time when preparing the new build jobs. As rpm is added machines at a rate of at least one per year over 4 years, every advancement in processing has an important effect on rpm continuing to be a price leader on the market.

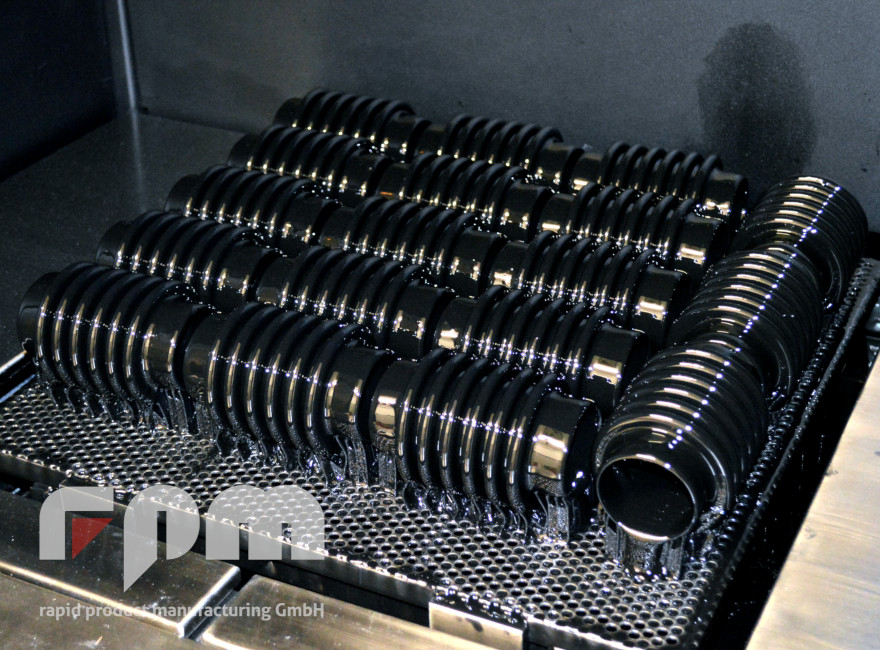

The final key benefit involves a centralization of the powder preparation to make it trackable and traceable from a central location. Driven by the series products like the canyon computer mounts being produced at rpm – it is very important to move towards centralized management of processing parameters. The ability to define and monitor material dosing and processing time allows rpm to guarantee consistent quality for our customers in the products we deliver.

We have come to rely on Farsoon over the past four years to supply us with industry leading production machines to keep rpm at the front of the pack in terms of both material variety and cost-competitiveness. The Powder Management System help us on both counts and adds the automation required to further stabilize SLS additive manufacturing in series production. Over half of our production is now small and specialty series products which has shifted our focus to reliability and machine up-time. Farsoon is a partner who thinks and develops for those same goals..

Dr. Jörg Gerken

Technical Managing Director

rpm rapid product manufacturing GmbH

Reliable Series SLS Additive Manufacturing

The integration of Farsoon Technologies’ Powder Management System aligns with rpm GmbH’s growth strategy, aimed at enhancing productivity and maintaining competitive pricing. As rpm GmbH continues to expand its production capacity, with recent acquisitions including the Farsoon Flight Dual-Laser system, investments in advanced processing technologies like the PMS contribute to sustained business growth and market leadership. Alongside post-processing tools like mechanical and chemical smoothing, colouring and automatic measurement tools – the pre-processing machine helps further ensure the quality of output. Each step towards stable production contributes to the confidence building in additive manufactured products as a direct competition to injection moulding for series products.

Dr. Tobias Todzy (Head of Sales, Farsoon Europe GmbH) emphasizes: “Farsoon is happy to have such a strong partner like rpm who believes in Farsoon and its technologies at an early stage and confirms again the partnership by installing the PMS to expand the series production with more automation. Four years – four machines plus a PMS! This is exactly the growth we are proud to have accomplished together.”

Through the incorporation of Farsoon’s Powder Management System, rpm GmbH underscores its commitment to operational excellence and continuous improvement as a leader in SLS additive manufacturing.

Farsoon Europe GmbH

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009, is a global manufacturer and supplier of industrial level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany to expand direct operations to Europe.

On April 17, 2023, Farsoon Technologies Co., Ltd. was publicly listed at the Shanghai Stock Exchange STAR Market through the Initial Public Offering of A-share. The stock code: 688433. Learn more: www.farsoon-gl.com

Farsoon’s Flight® Technology or Fiber Light® Technology takes advantage of powerful fiber lasers in place of the standard CO₂ lasers found in standard laser sintering systems. A fiber laser system is capable of delivering greatly increased power to the powder bed. Due to the more robust and stable nature of a fiber laser system as compared to a CO₂ system, Flight® Technology also provides increased laser longevity which is key when considering ROI for manufacturing applications. In addition, with its increased power and energy absorption characteristics Flight® Technology will be capable of accessing a much different range of processable materials and operational flexibility as compared to standard laser sintering systems, which allows for increased freedom for future AM material and application development. Due to the high scanning speed of the Flight® Technology is predestined for series production.