rpm invests to expand capacity for 3D printing series production and strengthens its partnership with Farsoon Europe GmbH

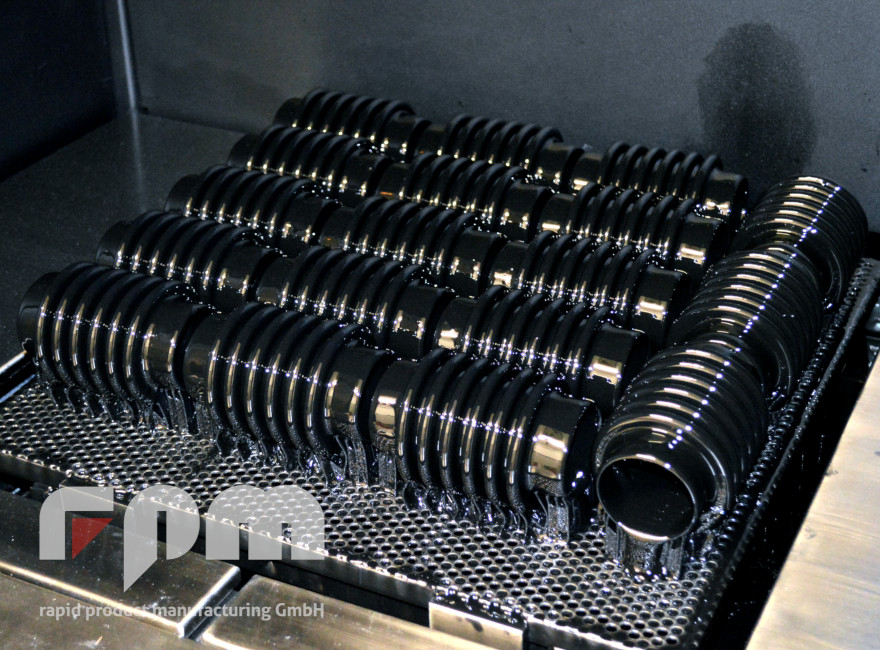

rpm, the highly experienced manufacturing service provider for plastic parts, has significantly expanded its production capacities for 3D-printed series products. The Farsoon Flight ® system will add additional speed gains to production and allow rpm to add system running predominantly black materials. The current investments enable rpm to meet the steadily growing demand for high-quality plastic parts and further consolidate its position as a reliable manufacturing partner.

Latest Farsoon Flight ®technology for rapid series production with additive manufacturing

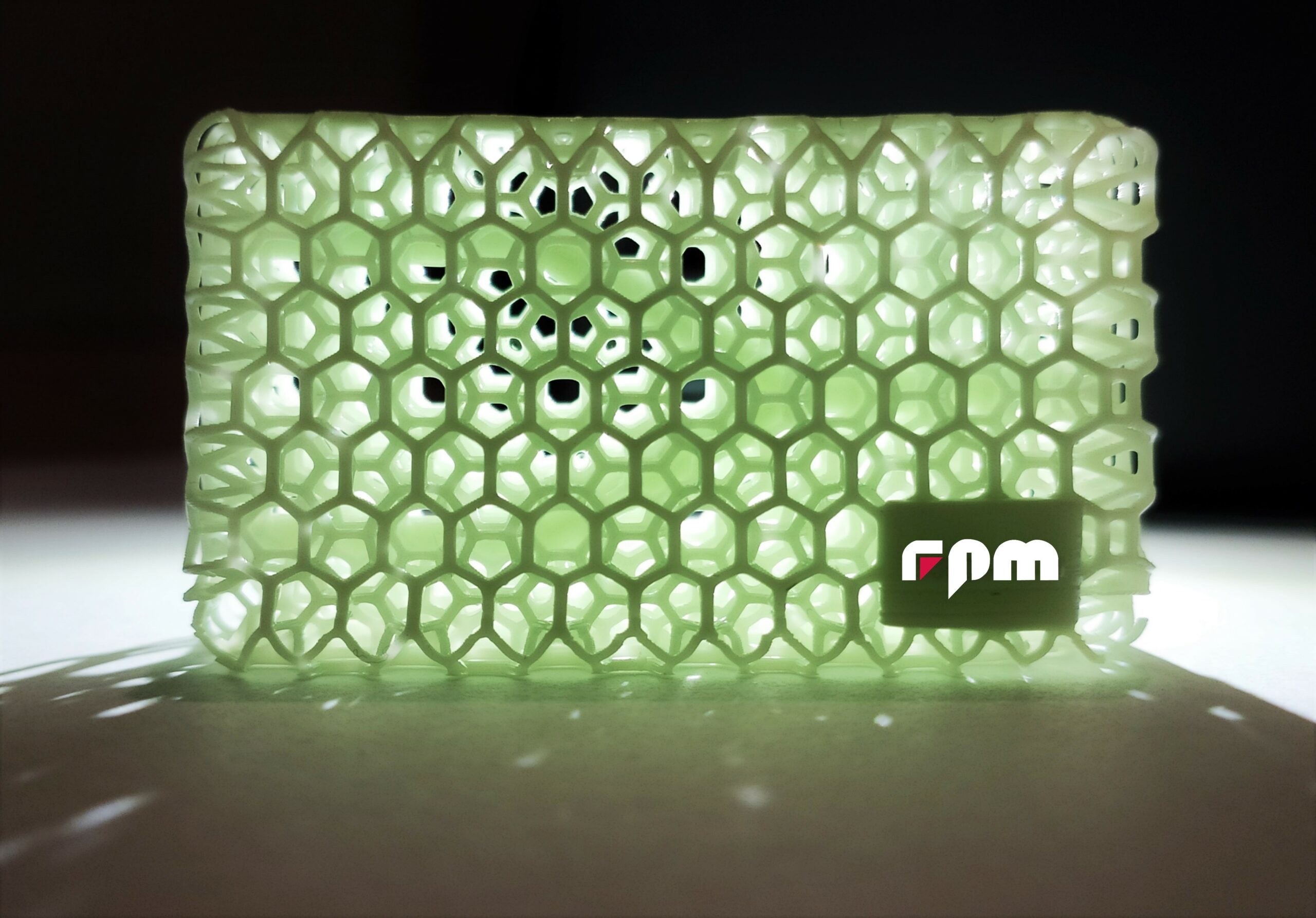

Since its founding in 1997, rpm rapid product manufacturing GmbH has developed extensive expertise in 3D printing, especially in the field of selective laser sintering (SLS). This long experience and expansion towards serial applications has enabled rpm to offer a wide range of solutions – from functional prototypes to series products. Since 2020, the systems from Farsoon, a leading global 3D printer manufacturer, have played a decisive role in the development strategy for rpm. The Farsoon machines are an excellent choice for variable production in a medium-sized company such as rpm, not only in terms of acquisition and operating costs, but also in terms of their technical specifications and flexible in optimizing and controlling production.

The latest expansion includes a state-of-the-art laser-sintering system, the Farsoon Flight ® HT403P-2 (see picture 1), with two lasers operating in parallel. This investment significantly increases productivity and flexibility for series production of 3D printed plastic parts. The associated peripherals for powder handling and build container management have also been optimized and supplemented by further investments to ensure a smooth and reliable production flow.

We really appreciate the close cooperation and technical exchange with the rpm team. It is particularly noteworthy that the rpm team, with their expertise in the 3D printing sector and in particular their technical director, Dr. Jörg Gerken, who recognized the opportunities that Farsoon Flight ® technology brings with it early on and can thus break new ground in the field of series production.

Dr. Tobias Todzy

Senior Technical Sales Manager, Farsoon Europe

With this investment, we are ideally positioned to meet the growing demand for high-quality 3D-printed plastic products. Our long-standing partnership with BASF Forward AM and our expertise in 3D printing enable us to offer customized solutions with best-in-class materials and give our customers a real competitive edge – from the first prototypes to the series product.

Dr. Claus Thomy

Managing Director, Strategy and Business Development, rpm GmbH

rpm’s expanded 3D printing production capacity will help the company efficiently meet the increasing demands of a competitive market. The investment underscores rpm’s commitment to staying on the cutting edge of technology and supporting its customers with superior solutions.

About rpm rapid product manufacturing GmbH

For over 25 years, rpm rapid product manufacturing GmbH (rpm) has provided functional prototypes and small series production for plastic parts in series 1 to 10,000. Their customers include key automotive manufacturers including Audi, BMW, Daimler, Volkswagen and their Tier supplier ecosystem as well as industry leaders from the industrial goods, consumer goods, mobility and medical industries. Since 1997 they have been a pioneer in using SLS additive manufacturing in series with a particular emphasis on technical parts, professional finishing, series production and specialty materials. In 2018, they invested in the Carbon technology and have become a leading production partner for DLS in Europe to expanding the applications of the technology. rpm GmbH is also the creator and trademark holder for the NylonMold™ and LostCore production processes, which enable small-series, fast-turnaround and cost-optimized production for PA6 parts. Their full portfolio includes 12 in-house technologies including injection moulding, RIM and PU casting and consulting competence for product development and redesign.

About Farsoon Europe GmbH

OPEN FOR INDUSTRY – Farsoon Technologies, founded in 2009, is a global manufacturer and supplier of industrial level polymer and metal laser sintering systems. Farsoon is the leading supplier of industrial AM technology in China with increasing growth in the international market. In 2018, Farsoon Europe GmbH was established in Stuttgart, Germany to expand direct operations to Europe.

On April 17, 2023, Farsoon Technologies Co., Ltd. was publicly listed at the Shanghai Stock Exchange STAR Market through the Initial Public Offering of A-share. The stock code: 688433. Learn more: www.farsoon-gl.com

Farsoon’s Flight ® Technology or Fiber Light® Technology takes advantage of powerful fiber lasers in place of the standard CO₂ lasers found in standard laser sintering systems. A fiber laser system is capable of delivering greatly increased power to the powder bed. Due to the more robust and stable nature of a fiber laser system as compared to a CO₂ system, Flight® Technology also provides increased laser longevity which is key when considering ROI for manufacturing applications. In addition, with its increased power and energy absorption characteristics Flight® Technology will be capable of accessing a much different range of processable materials and operational flexibility as compared to standard laser sintering systems, which allows for increased freedom for future AM material and application development. Due to the high scanning speed of the Flight® Technology is predestined for series production.

Want to find out more about our specialty materials?