rpm reaches a new level of data Security and information management with TISAX certification renewal

Since 2017, rpm – rapid product manufacturing GmbH has successfully completed two TISAX Certification assessments (Trusted Information Security Assessment Exchange). In June 2020, they completed their second certification cycle. This achievement represents a continuous investment and upgrading of their information security system for serving top tier automotive customers. But the high data security procedures also benefit customers across industry verticals, in particular for medical, machining and consumer goods manufacturers.

TISAX Certification for Information Security in Plastic Part Production

For over 20 years, rpm has counted leading automotive OEM and tier suppliers among their customer base. In 2014, they underwent a first audit of their information security system to meet the requirements of the Volkswagen concern, what later became the TISAX Certification (Trusted Information Security Assessment Exchange) standards and also influenced the ISO/IEC 27001 standards. Over the past six years, the requirements have become significantly more rigorous as a set of policies to ensure proper data processing and a standardized protection system along the supply chain. This current approval is the second formal TISAX Certification and represents upgrades in server architecture, employee data handling policies and access systems within rpm.

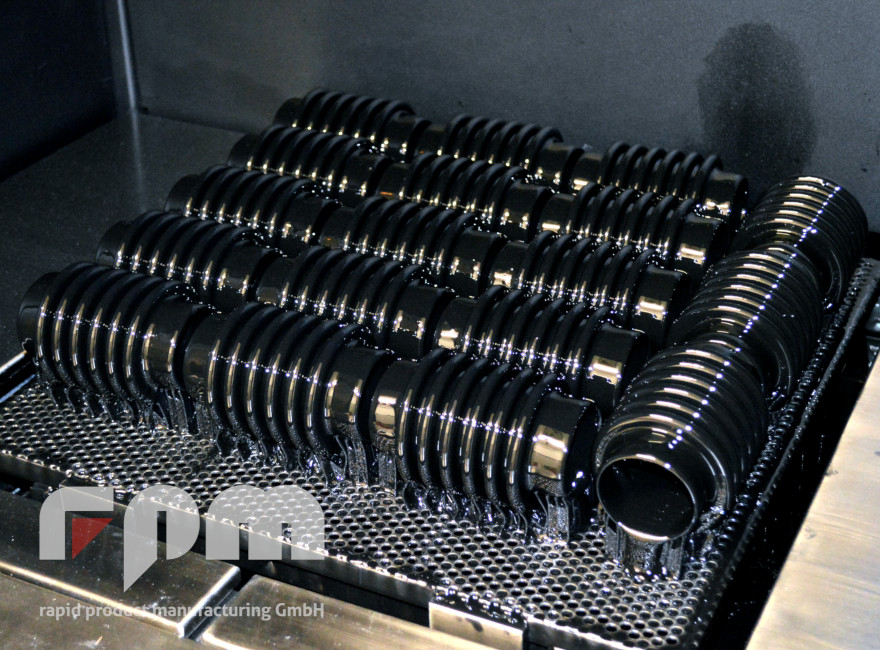

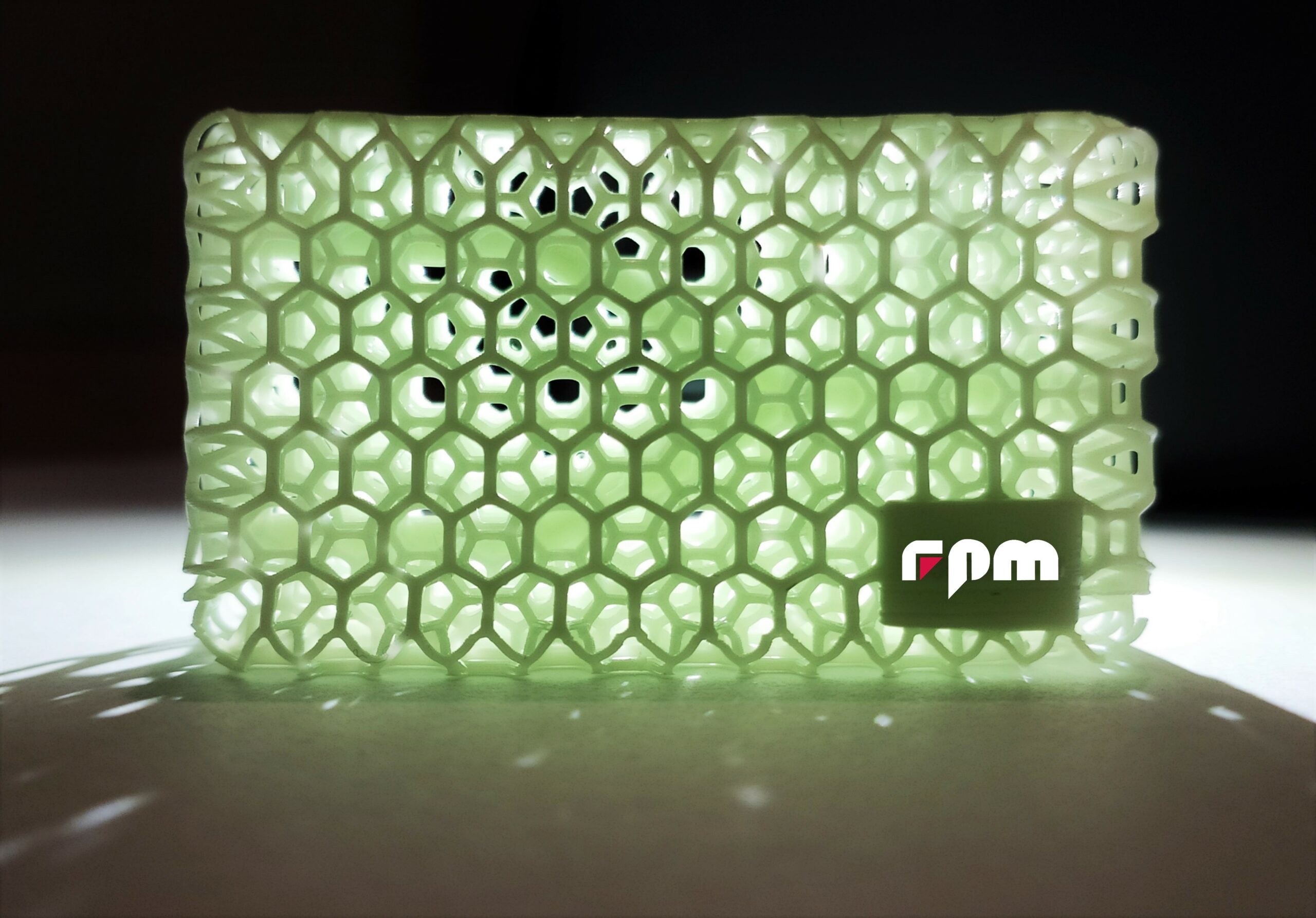

As the plastics producer has expanded their customer base into medical, consumer, machine building and mobility applications and increased their footprint in additive manufacturing with the addition of DLS technology from Carbon, they have seen that the requirements for secure data handling are rising across these industry segments. By improving all security policies, rpm is maintaining their role in securely process part information for leading manufacturers across Europe.