Plastic Parts in Series 1 to 10,000

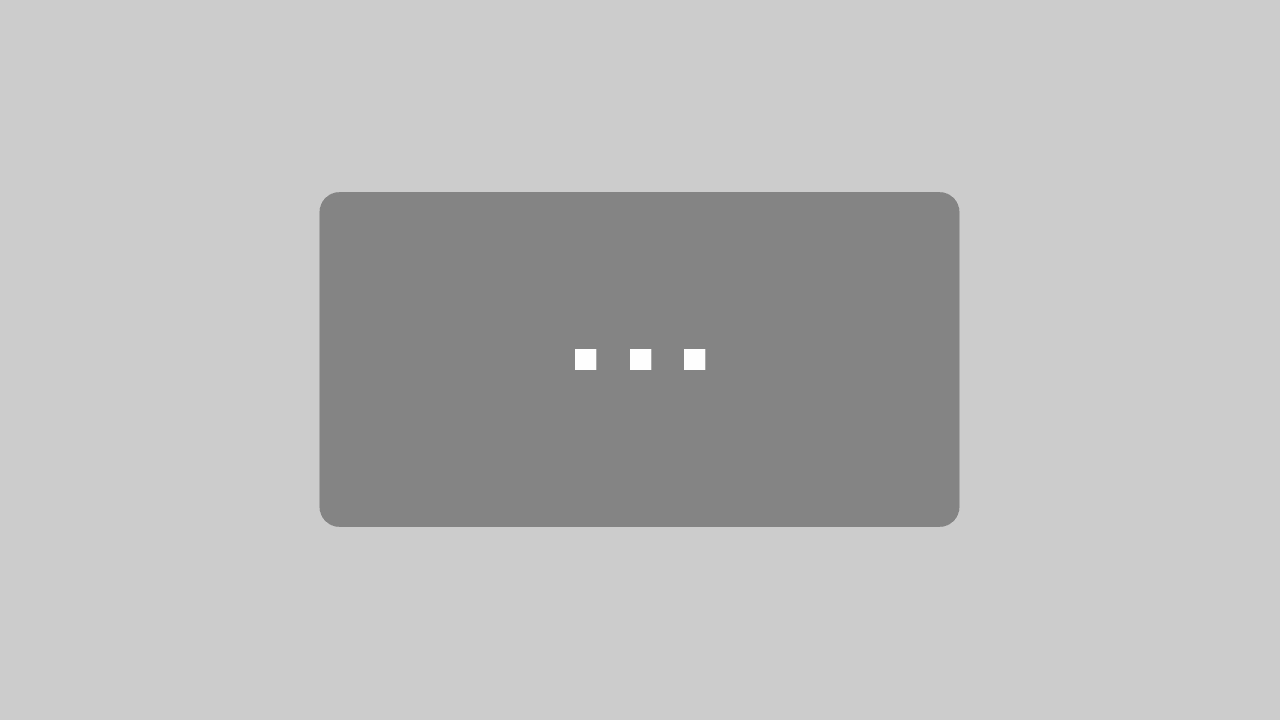

rpm focuses on SLS, DLS and DLP, three 3D printing technologies that scale all the way from prototyping to full series production.

more details

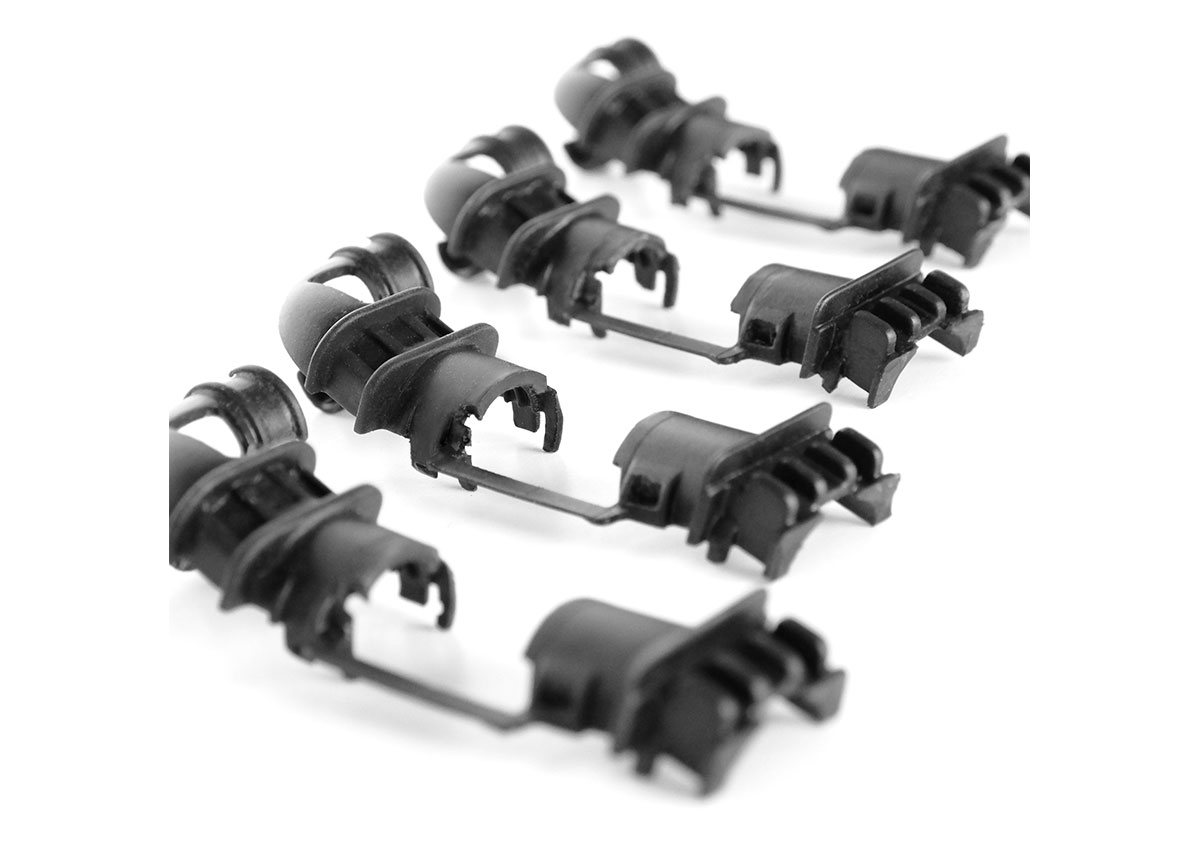

From series 20 to 200 parts, vacuum casting into soft tooling opens a wider material palette (Polyurethan, Polyamide, RIM resins) and competitive pricing, also for end-use technical parts.

more details

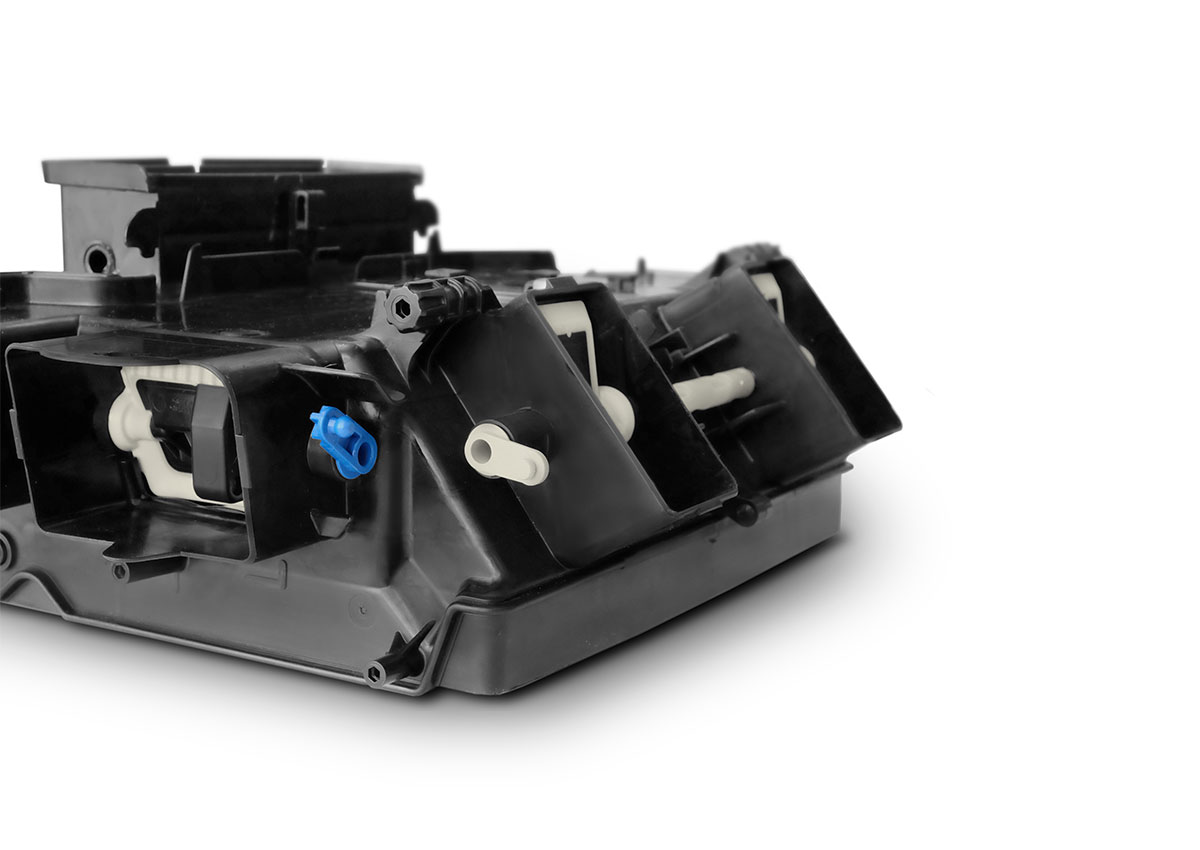

Scaling up to 200 or 5,000 parts you often need an injection moulding partner producing in small series. rpm focusses on rapid moulds in aluminum and steel to produce technical parts here in Germany.

more details

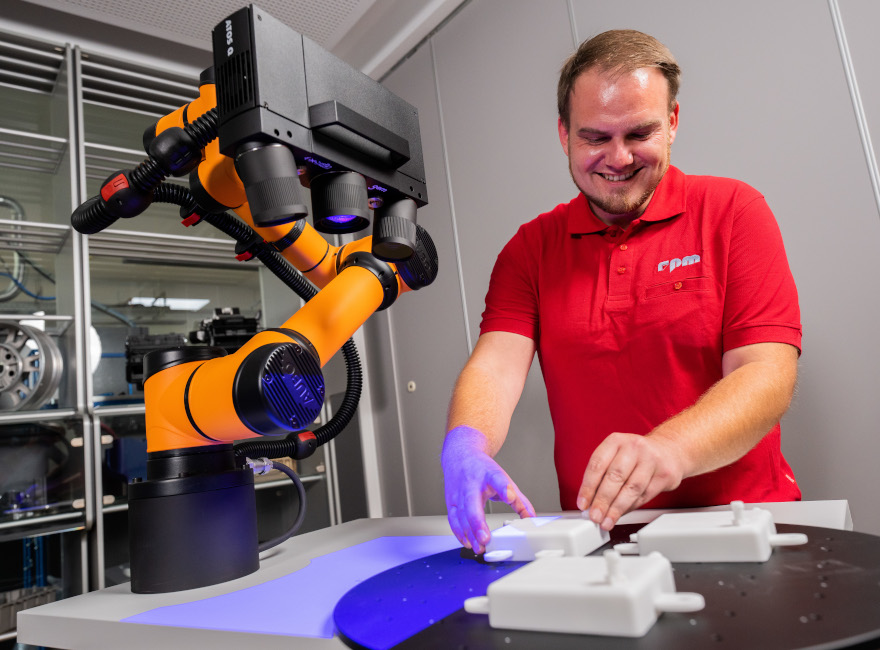

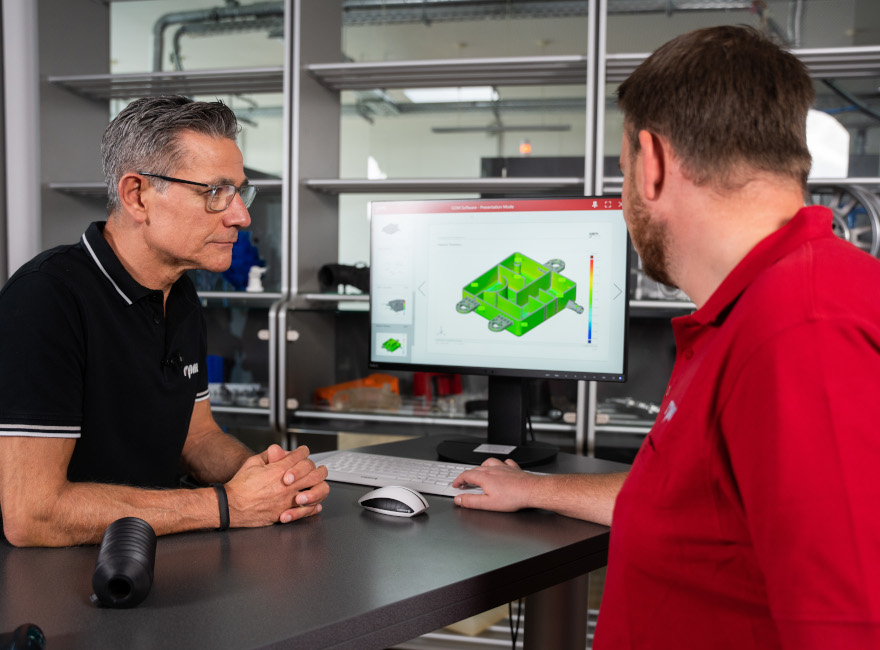

As supplier to German industrial goods and automotive companies for decades, quality is at the heart of rpm from production to testing to product assembly.

more detailsRapid Product Manufacturing in the Digital Factory

At rapid product manufacturing, we bring products to life with a minimum of tooling and a maximum of performance. As technologies advance, we stay at the forefront – from DLS for series parts, 3D printing in specialty materials with SLS or as a pioneer in polyamide casting with NylonMold™.

Pioneers in Plastic Part Manufacturing

rapid product manufacturing produces parts and develops engineered solutions for leading European companies from industrial goods to automotive to consumer products. We treat our parts to high quality standards (ISO 9001:2015) and take your data security (TISAX) and product ideas just as seriously.

rpm is your competitive advantage in digital, small-series manufacturing.

Years of Experience

Projects per Year

Parts per Year

Additive Manufacturing in Small and Medium Sized Series

Technology and material advances over the past years have brought additive manufacturing to end-use products. Equipped with the latest Carbon DLS technology, the largest format DLP printer the Xtreme 8K and SLS machines from Farsoon, rpm is focused on high quality, volume AM production.

Plastic Casting for Prototypes and Specialty Series

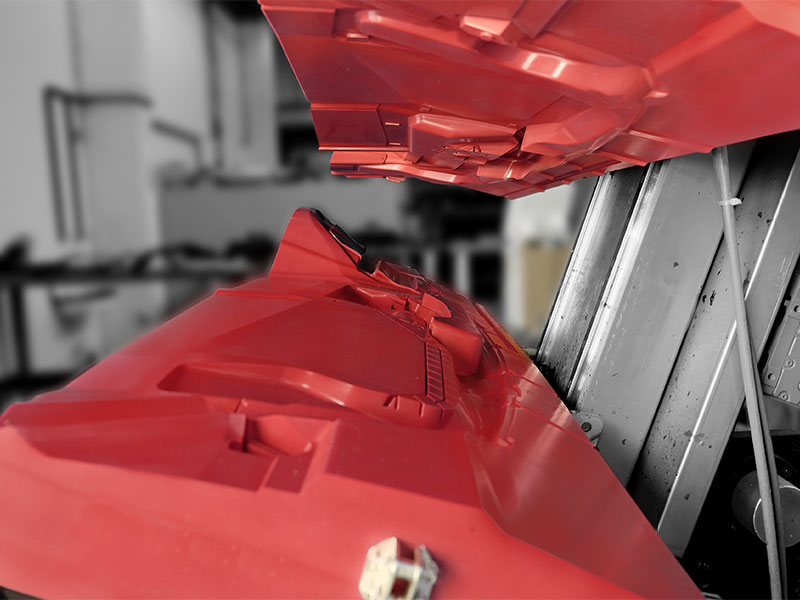

rpm rapid product manufacturing is developer and trademark holder for NylonMold™, one of the first PA6 casting technology for technical parts. Alongside PU moulding and RIM (Reaction Injection Moulding) we produce everything from medical casings to bumpers for semi-trucks.

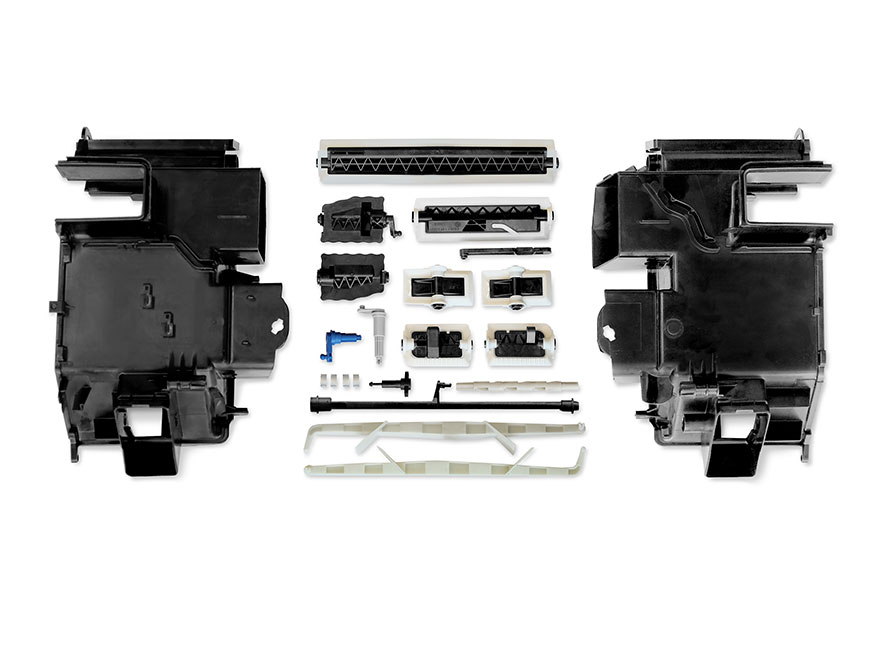

Injection Moulding in Pre-, Small or Specialty Series

Our injection moulding is focused on small lot sizes with shortest possible lead times. With rpm you have a local partner that understands technical requirements and can react quickly, even in complex projects, as all steps from tooling design to tool machining, part injection and finishing are done in-house.

Finishing, Assembly and Quality Assurance

To supply spare parts and specialty series assemblies requires that extra step of finishing. rpm has a team dedicated to enhancing our final products, from machining to tolerance, assembling multiple components or measuring and testing produced parts. Many of our processes also allow for series finishes like painting, lamination or protective coating for end-use parts.