LARGE FORMAT RIM PARTS IN SPECIALTY AND SMALL SERIES

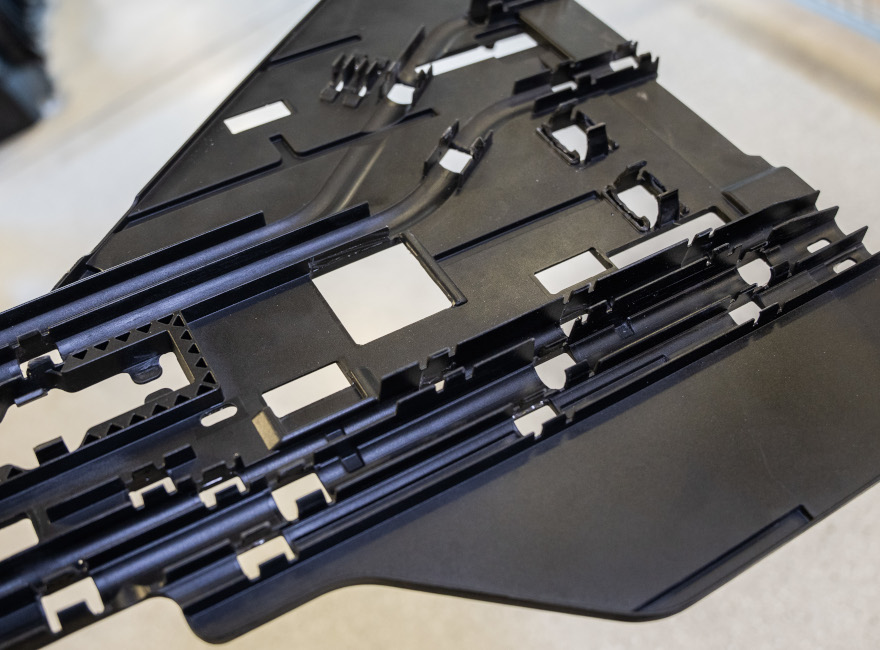

One of the niches for rpm is the casting of technically accurate, large format parts using RIM (Reaction Injection Moulding). This process uses two-component materials that can be a direct replacement for series materials. The parts can be finished with painting, lamination or the addition of metal components such as inserts. Once our RIM materials have been validated by the customer, the process is suitable for small series production in low-volume applications and aftermarket parts.

RIM is an attractive choice for large format plastic parts in small series. The manufacturing process offers the combination of low-cost tooling and part repeatability. The parts which are created in RIM have 100% functionality and can even be cast directly into metal molds. A range of polyurethane materials is available to match product characteristics similar to ABS, POM, foam or rubber elements. A typical order volume is 20-50 parts but some projects reach volumes of 500 parts per month

Trusted Materials

Production Stations

Functional Parts

SMALL SERIES, LARGE FORMAT FUNCTIONAL PROTOTYPES IN RIM

Every purchaser knows that the initial metal tooling is the biggest investment and driver for total cost. As the part size grows, those tooling cost increase significantly faster. rpm began producing large format parts in milled plastic tooling to significantly reduce the investment and speed up part delivery. The plastic block material can produce 200-300 parts without a reduction in quality, and the first part delivery can already be made in 3-5 weeks.

SPARE PARTS IN RIM FROM 20-2,000 UNITS

rpm is increasingly using RIM to act as a local partner for part production and provide supply chain stability. We produce spare and aftermarket parts over years and decades from the same moulds for our customers. During the COVID crisis of 2020, projects that were extended using existing moulds made up 65% of our part volume. Once the RIM materials and the rpm finishing methods are approved by our customer, a wide selection of parts can be covered using this low-volume, cost-efficient production.

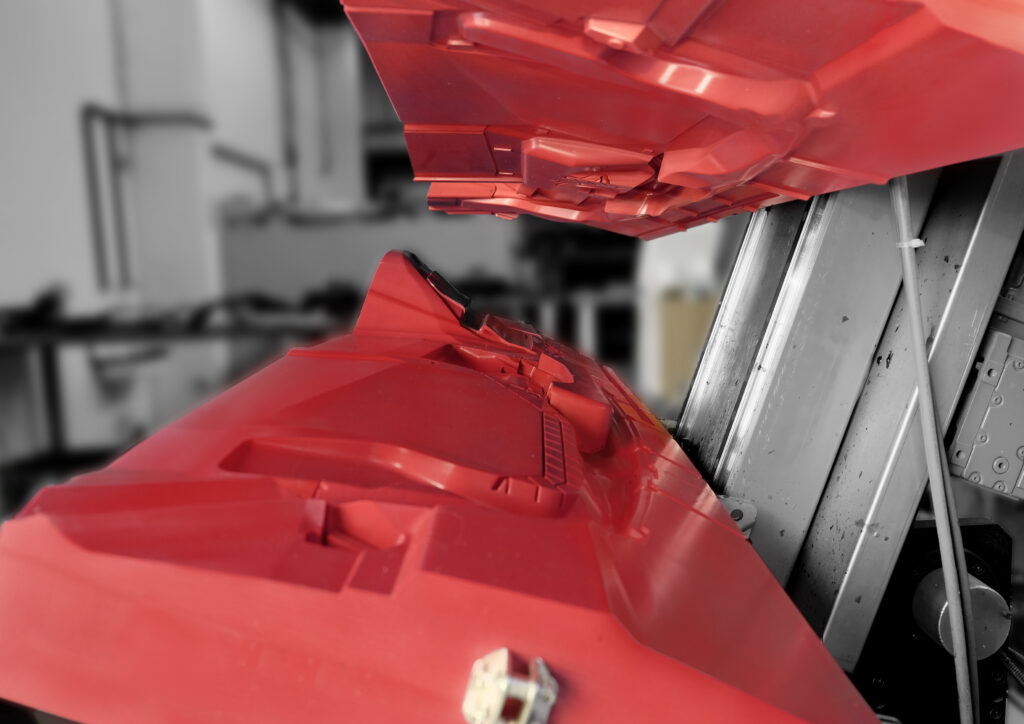

SERIES-QUALITY FINISHING AND PAINTING FOR END CUSTOMERS

For end-use applications, long-term material performance is a key variable. The RIM materials have mechanical properties that match many series materials. In addition, each part can also be finished with painting, lamination or even cladded with leather. That coating provides an extra sealing and protection for the parts out in the field. rpm has their own painting facilities for standard projects and has developed partnerships over decades to execute more complex finishing requests.

AN EXPERIENCED RIM PRODUCTION PARTNER TO ENSURE PROJECT SUCCESS

rpm has produced small series parts using Reaction Injection Moulding for over 15 years. Approximately half of those parts are for specialty series in end-use applications with a full quality assurance chain. This extensive body of knowledge for design, production and finishing is brought into our evaluation of each new project we receive. Small design modifications can often make a big impact on the successful production and repeatability of a part. Working with rpm brings you in contact with a leading small series partner for RIM parts.