ADDITIVE MANUFACTURING IN SMALL SERIES WITH DIGITAL LIGHT SYNTHESIS (DLS)

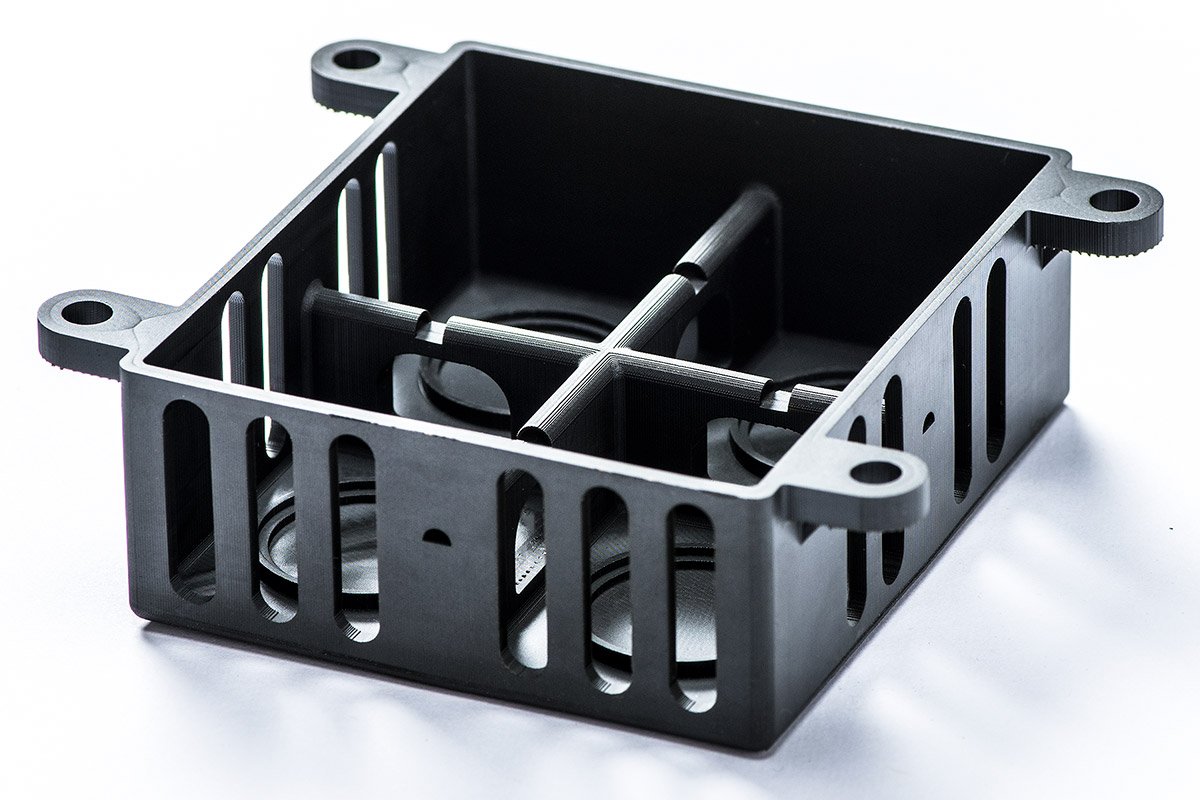

In 2018, rpm joined the pioneers of DLS in Europe to begin producing parts. Additive manufacturing with this technology brings end-use materials, fast print times, and a scaling factor that is particularly interesting at 50+ parts. Since 2020, more than half our DLS production has been small series parts.

The full palette of engineering materials is offered at rpm. While the majority of applications tend to center around EPX 82 for electronics and industrial goods, RPU 70/130, or EPU 40 for automotive and EPU 41 for consumer goods, we regularly produce parts in more exotic materials for specific applications.

We are able to use more than 24 years of experience in plastics production to recommend the best design, engineering and material mix to optimize for DLS. Having in-house milling also allows us to achieve even tighter tolerances. We see additive manufacturing in DLS as one of the key growth areas over the next several years.

Materials

Hours

Parts

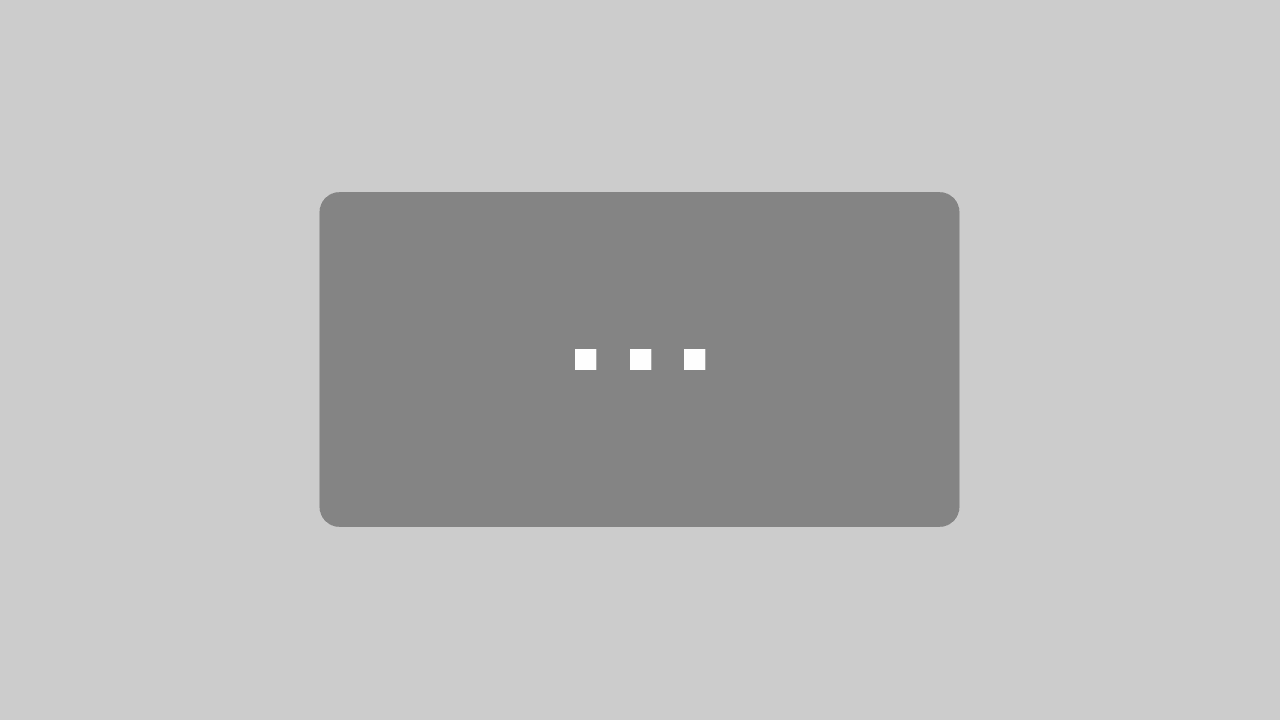

3D PRINTING TECHNICAL AND CONSUMER PRODUCTS

While DLS had lots of initial success and visibility with consumer products in elastic materials, we at rpm are increasingly finding valuable use cases in small series technical products. The best cost applications are the size of a palm of the hand or smaller for optimal stacking per build job. But rpm also produces larger parts with complex inner or outer geometries that can only be achieved with DLS in series of 200-300 parts per quarter.

SERIES MATERIALS WITHOUT INJECTION MOULDS

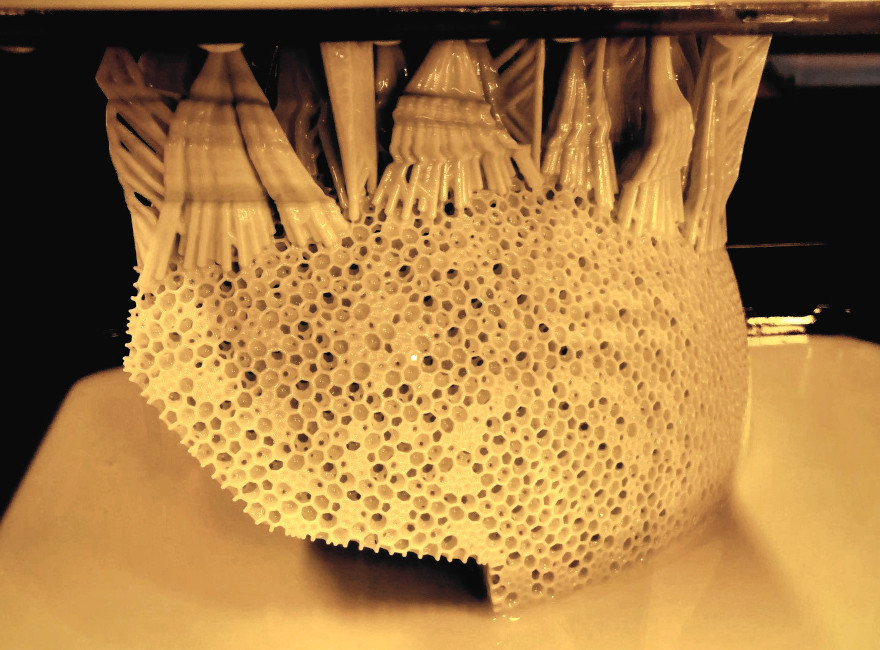

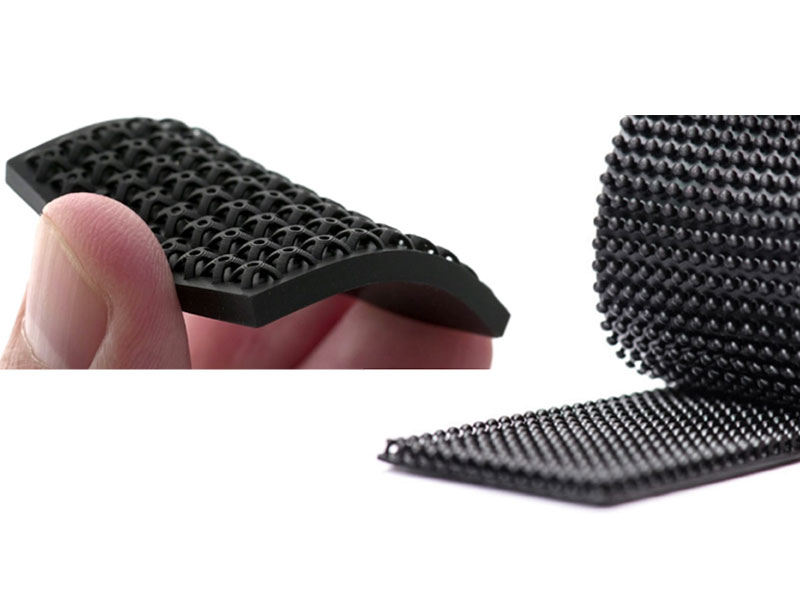

The material palette in DLS covers use cases in electronics, machine parts, pneumatic devices and includes IMDS listing for automotive and mobility applications. The continuous curing of the resin material ensures a minimal layering and allows the creation of complex textures on the part surface.

The two-phase hardening produces isotropic parts that are suitable for a wide range of technical applications. Those resulting parts closely match injection moulded performance and even have certifications like IMDS and UL 94 flame testing without requiring any up-front investment in injection moulding metal tools.

DLS TECHNOLOGY, FROM PROTOTYPE TO PRODUCTION

For new product development, one of the hidden costs is requalifying materials and processes when switching from prototyping to pre-series to series manufacturing. By designing for DLS, the entire prototype to production process can be carried out on one material and one technology to limit validation costs. Because “design iterations come for free”, many of our customers produce three or more designs per production cycle.

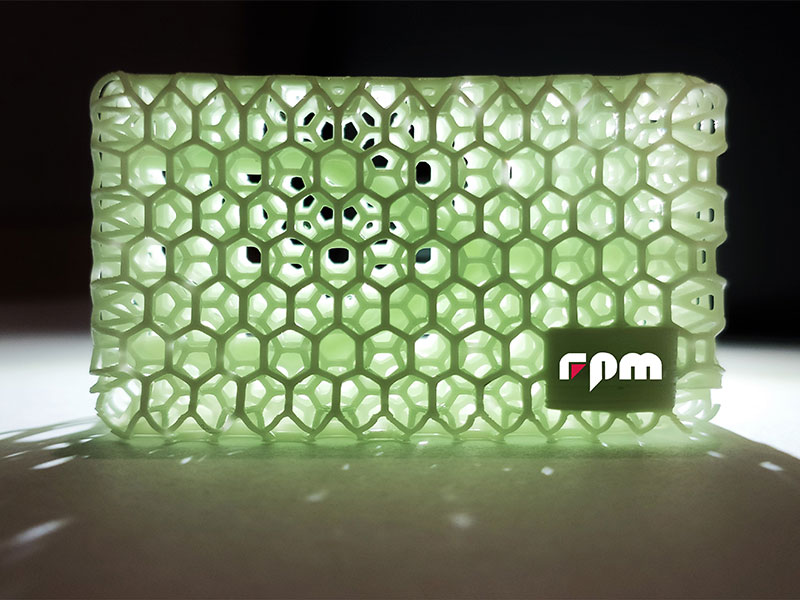

COMPLEX GEOMETRIES WITH ADDITIVE MANUFACTURING

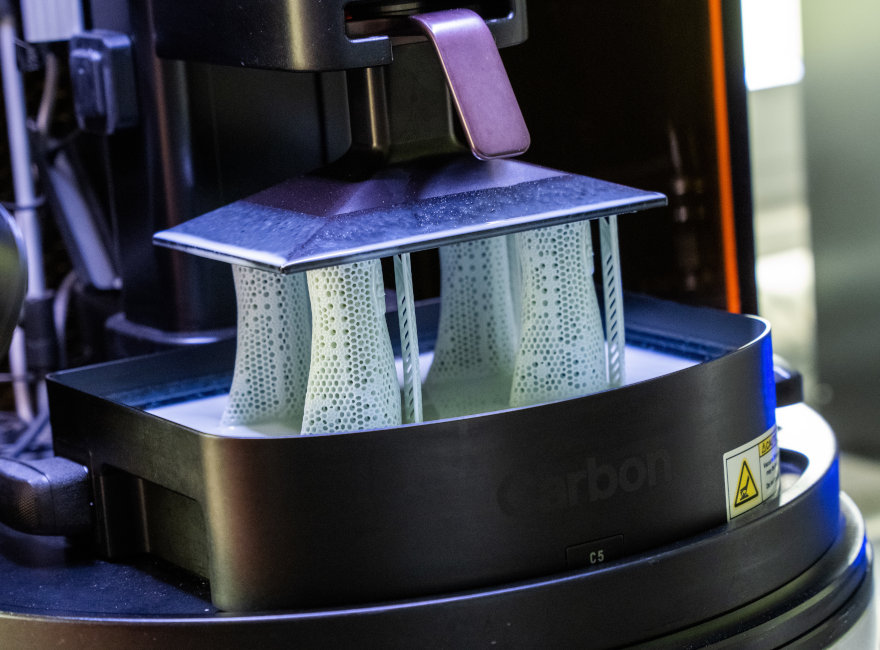

Companies are increasingly turning to 3D printing for high-performance, end-use applications with specialized geometries. In particular the ability to integrate channels within the part according to a few simple design rules can have a strong effect on part performance. Customised lattices with varied mechanical response at different areas enable a single part to replace two or more other components. Over the part lifecycle, this reduces assembly cost, logistic overhead, and limits supply chain risk.

DESIGN for DLS

Producing parts in the DLS technology requires a different approach than other additive manufacturing technologies. The success and cost of the part are highly dependent on minimising support structures. Often a few simple adjustments can make a significant difference to the cost and performance of a part. When you work with rpm, competent technical advice and professional experience is part of every conversation to ensure you get the best result possible from the technology.

LIGHTWEIGHTING PRODUCTS WITH REGULAR LATTICE STRUCTURES

The Carbon Design Engine is a powerful software which allows rpm to quickly and efficiently add lattices to components or entire parts of a design. We often engage in a short development cycle with our customers to produce a few test blocks with targeted parameters. The customer can then validate the mechanical function of a part before moving into production. We pull from years of experience to quickly achieve the project target.

CUSTOMIZED LATTICES FOR NEXT-GENERATION PRODUCT DEVELOPMENT

For more complex parts which rely on additive manufacturing of variable lattices, we also have a team and workflows in place. Depending on the project demands, we are able to generate custom lattices to a specific mechanical function, integrate channeling, improve performance, and generate lattices based on heat maps or scanned shapes. We also have well-established relationships with software partners to create standardized workflows for mass manufacturing of customized parts.

APPLY TEXTURES TO 3D PRINTED END-USE PRODUCTS

The high-resolution output of DLS allows for placing textures directly on the surface of parts. The most common is a fine-grain noise texture to mimic injection moulded parts. But increasingly textures are being added to improve the grip of parts in automation systems, integrate with design of interiors and furniture or please the eye in consumer products. With a smart design, the textures can be applied with a minimum of additional effort to create outstanding parts.