rpm awarded public funding to research complex, elastic Lattices using 3D Printing

rpm – rapid product manufacturing is the leading partner in an ZIM research grant to develop complex elastic Lattices using 3D Printing. The grant, “Development of elastic lattice structures using additive manufacturing for various applications” came from the German AiF. Central to the project is the Digital Light Synthesis process and EPU41/EPU40 materials from Carbon 3D. Over the next year, rpm will lay the scientific foundation for applications with partners in the industrial goods and consumer goods industries.

3D Printing Technology Advances, New Applications

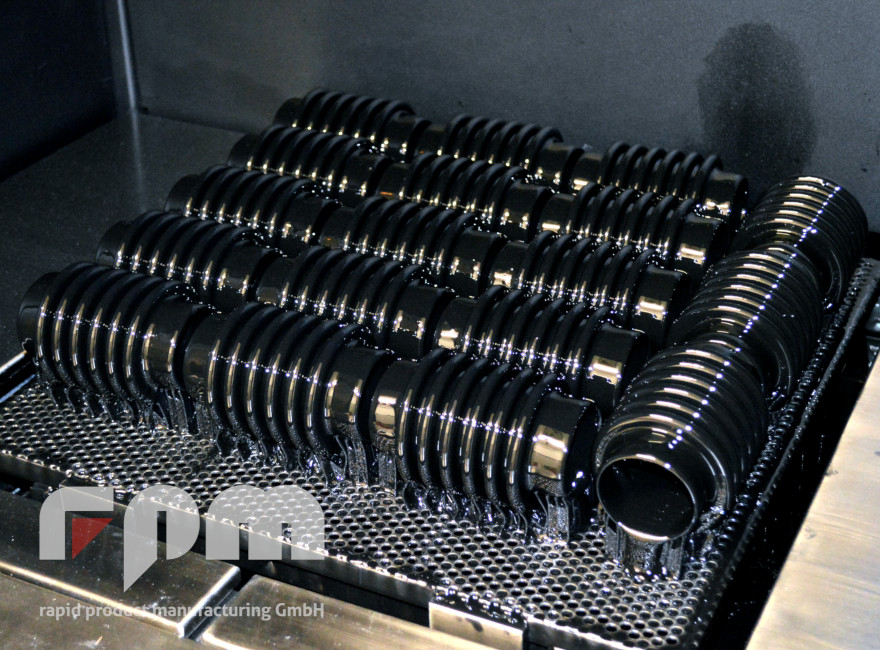

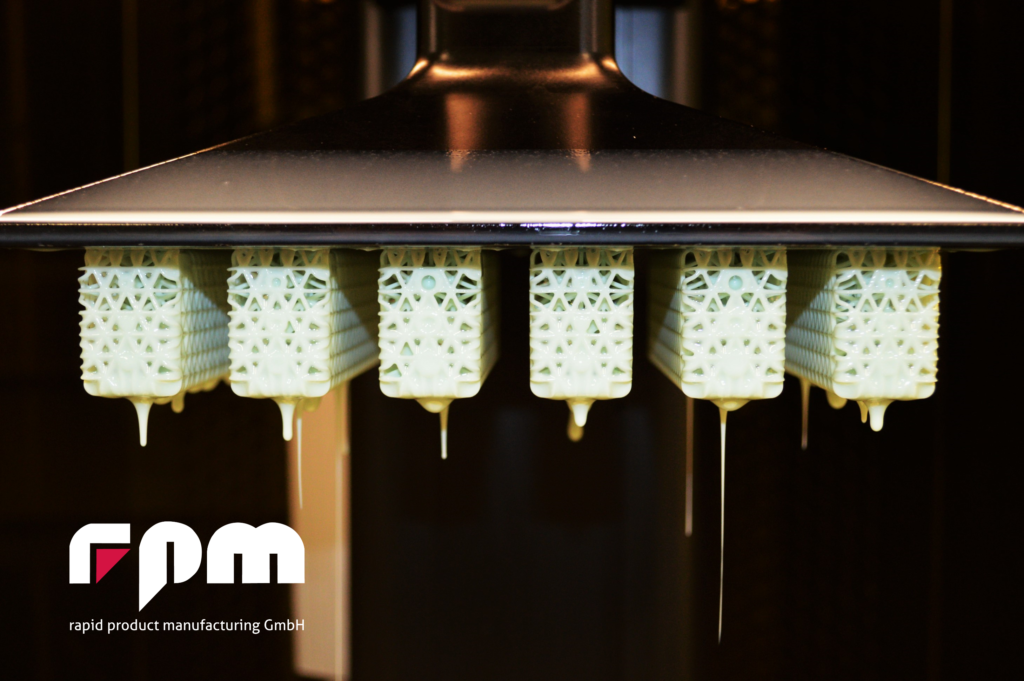

In 2018, rpm became one of the first service providers in Europe to adopt the Digital Light Synthesis (DLS) technology from Carbon3D. With DLS, rpm saw a next-generation AM technology that optimized production, provided high-resolution parts and series-ready materials. This combination covered a different production need than their other in-house casting technologies and brought a better business case to current customers. Over the past three years, continued development of software, material science and post-processing systems has brought price and production timelines even lower.

In 2020, rpm produced more serial applications (reoccurring orders of 200 – 1,000 units in intervals of 2-3 months) than prototype parts with DLS. Seeing this production change validated the hypothesis with which they invested in the technology. Serial additive manufacturing has arrived and it is driven by new technologies.

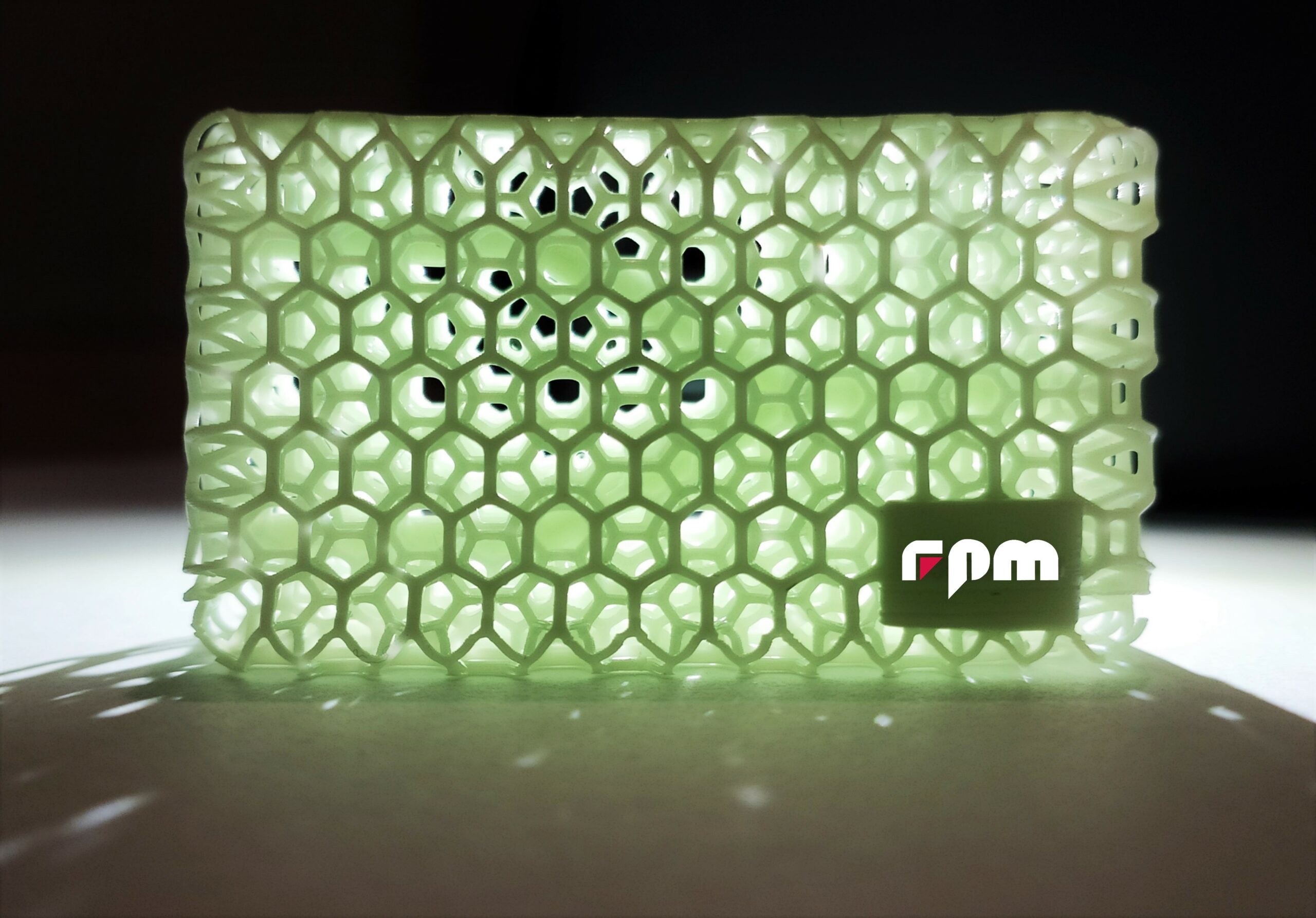

For the next few years, rpm is putting a significant focus on creating a knowledge bank of materials, design rules and applications using lattice structures. The goal is to be a leading partner to develop next-generation applications and in-house production. Lattices are one of the most-important.

This grant focuses on DLS because Carbon3D put serial production at the forefront of their development. The material options and reliability of machine processes allow us to cover a variety of new business applications at a competitive cost point. Even more importantly because the material is standardized and validated, it also prints exactly the same way the second, third and twentieth time. When rpm adds improved part product performance using lattice structures that are only available in additive manufacturing, we are establishing truly superior product solutions.

Dr. Claus Thomy, Managing Director, Sales

rpm – rapid product manufacturing GmbH

ZiM Project Grant through AiF

The ZIM project, was awarded by the AiF (Arbeitsgemeinschaft industrieller Forschungsvereinigungen „Otto von Guericke“ e.V.) to support mid-sized German businesses in research and development. The official grant title is “Development of elastic lattice structures using additive manufacturing for various applications” and is being supported on both the development and technical side by the Institute for Microtechnology at the University of Braunschweig. The application areas were selected by based on roadblocks rpm has encountered with customers looking to specific DLS applications over the past years. They are all mechanical concepts where lattices can bring specific product value but the application requires a certain level of research and development before it is ripe for production. This project will overcome the hesitation from customers to pay for uncertain outcomes and provide that intellectual property around production directly to rpm.

rpm will move through a project plan and work with the microsystems experts at the Institute for Microtechnology to produce a variety geometries for evaluation, move through mechanical and performance testing and optimize process parameters for serial production. The six applications were also selected so that each set of learnings will augment the overall production knowledge of rpm. The R&D stage are each critical to address part performance, user experience, and cost optimization so that the full product lifecycle is qualified. When the project closes in spring of 2022 will have a series of demonstration models and process parameters that can be taken to key industry producers and added into products.

Lattice Structures with Internal Channeling using 3D Printing

Most of the research areas that were identified include adding channeling within the elastic lattices to enhance product function. These structures are challenging from the perspective of production and mechanical properties, but can enable a new class of products only possible using additive manufacturing.

The applications being researched includes:

- Directed cooling channels (active and passive) within padded structures

- Use of pneumatics to control mechanical function

- Using liquid to control mechanical function

- Integrating thermal cooling and heating within elastic parts

- Influencing dampening performance with air and liquid

- Integrating flow systems within elastic parts

To create a reliable production stream for these flexible lattices with thin integrated channels rpm needs a precise calibration of product function, lattice design, material reliability and machine performance. The ZIM research funds will support the development of these pioneer production processes. The lessons and processes will be appliable for a wide variety of products from electronic goods to automation and from high-end consumer goods to performance machines.

DLP technology allows us to take a different approach to product and part design. rpm recognizes that lattices will continue to be a key application from the both the technological and material perspectives. After working with regular and irregular lattices in EPU materials for more than two years, we are ready to establish this next generation of production. The ZiM grant gives us the extra fuel we need to perform the necessary R&D and prepare for rapid product manufacturing.

Dr. Jörg Gerken, Technical Managing Director

rpm – rapid product manufacturing GmbH